Plastifying systems

Introduction:

Since 1995, Elkrem specialists have gained a number of valuable experience in the selection of welding materials and strengthening of metal surfaces. We actively use experience and knowledge in the plastics processing industry in the production, strengthening and regeneration of plastifying systems. We specialize in providing improved machine components exposed to extreme wear, especially in recycling, processing of rigid PVC, WPC and plastics with a high content of additives. For the processing of less demanding materials, we can choose an equally durable weld which translates into increased resistance to abrasion.

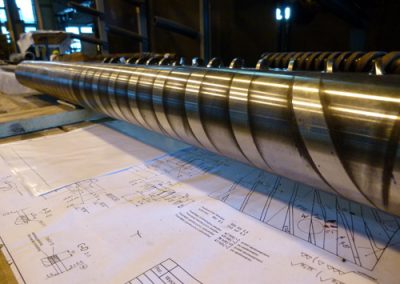

New plastifying systems:

As a production company, we understand the needs of our customers to reduce the risk of unexpected production stops. For this purpose, we provide new plasticizing systems made of the highest quality materials and made on precise modern CNC machines under the watchful eye of experienced technologists and constructors. Our domain is focusing on production repeatability, high durability of manufactured parts and efficient customer service.

To order new screws and cylinders, we offer measurements and preparation of detailed documentation in the form of technical drawings of individual details at the Customer’s site and at our company headquarters.

At Elkrem, you can order screws and cylinders in the nitrided and / or bimetallic version according to the following technical scope:

| Type | Diameter range | Length range |

|---|---|---|

| Single system | 20 mm - 200 mm* | 500 mm – 8.000 mm* |

| Parallel twin system | 50 mm – 135 mm* | 850 mm – 6.000 mm* |

| Segment systems | individual verification | individual verification |

| Twin conical systems | all | all |

*- it is possible after individual verification to make out of range.

For extreamly demanding processing, we offer bimetallic cylinders with a hardness (in the range): 60-69 HRC and a thickness of 2mm internal alloy layer. The parameters of the bimetallic layer are selected individually.

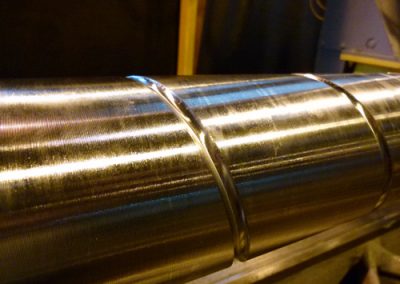

Reconditioning and hardfacing of plastifying systems:

Our many years of experience in selecting welds for our clients allows us to propose the most suitable welding material for strengthening the screws, compatible with the application of a given plastifying system. In our opinion, the best method is to weld the coils using the plasma method (PTA). The plasma beam reaches a temperature of 15,000-20,000 ℃, which effectively fuses the weld into the coil, which is not possible when welding with the popular TIG or MAG method (temperature around 3000-4000 ℃). In this way, we practically eliminate the risk of falling of the weld during the system operation and ensure production continuity. At the customer’s request, we allow cheaper and less durable solutions like welding with special welding wires (hardness 250HB – 69HRC), including those containing sintered carbides.

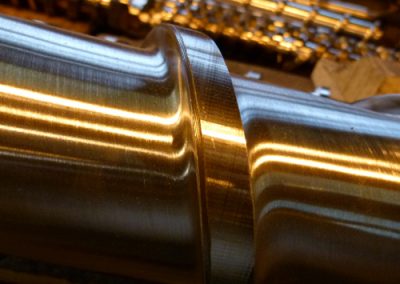

We select the weld based on the composition of the native material of the screw and on the basis of information about the processed plastic. In our portfolio we have Stellite welds and powders made for us by the best European PTA powder factories for the toughest processing conditions. The powders used by us ensure hardness in the range of 50-65 HRC and high content of precious alloying additions. Each case is considered individually and we choose the proper parameters of the weld.

If the screw is only nitrided, the regenerated screw will have a higher strength than the new one. Therefore, regeneration takes on the character of refinement and strengthening of coils. The remanufactured part will last much longer and maintain the high performance of the machine.

For the fastest regeneration, it’s best to contact us and schedule the repair in advance.

| Type | Diameter range | Length range |

|---|---|---|

| Single system | 20 mm - 200 mm | 500 mm – 6.000 mm |

| Parallel twin system | 50 mm – 135 mm | 850 mm – 5.000 mm |

| Segment systems | only new realization | only new realization |

| Twin conical system | all | all |